Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Welldon PE Film Clear Acrylic Sheet Quality Plexi Glass Manufacturer

-

USD 1.40 ~ USD 2.50/kilogram

500/ kilogram (Min. Order)

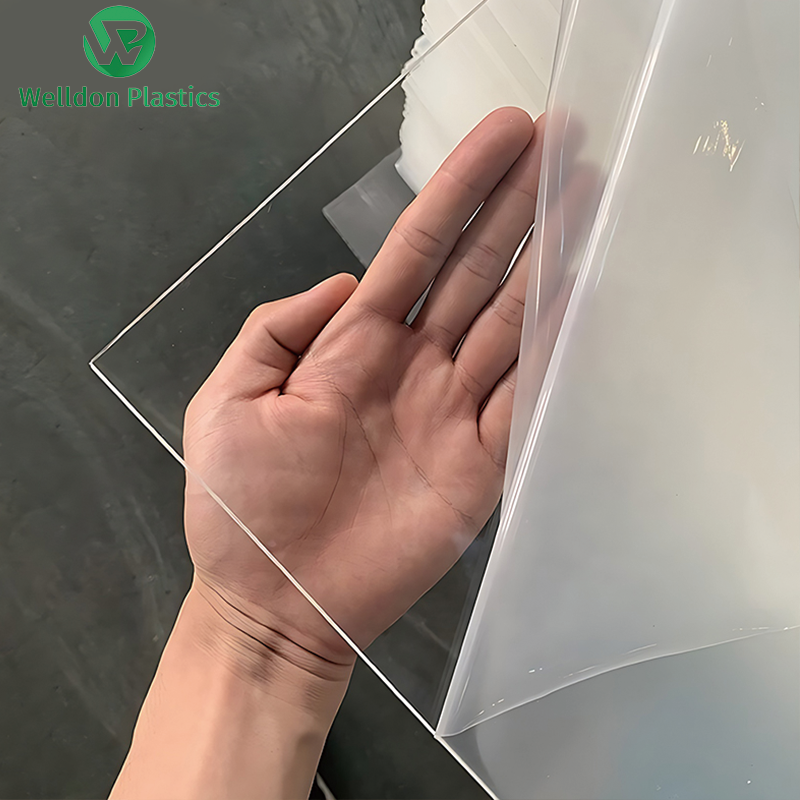

PE (Polyethylene) film acrylic sheets are acrylic sheets that are laminated with a layer of polyethylene film.

Manufacturing Process

-

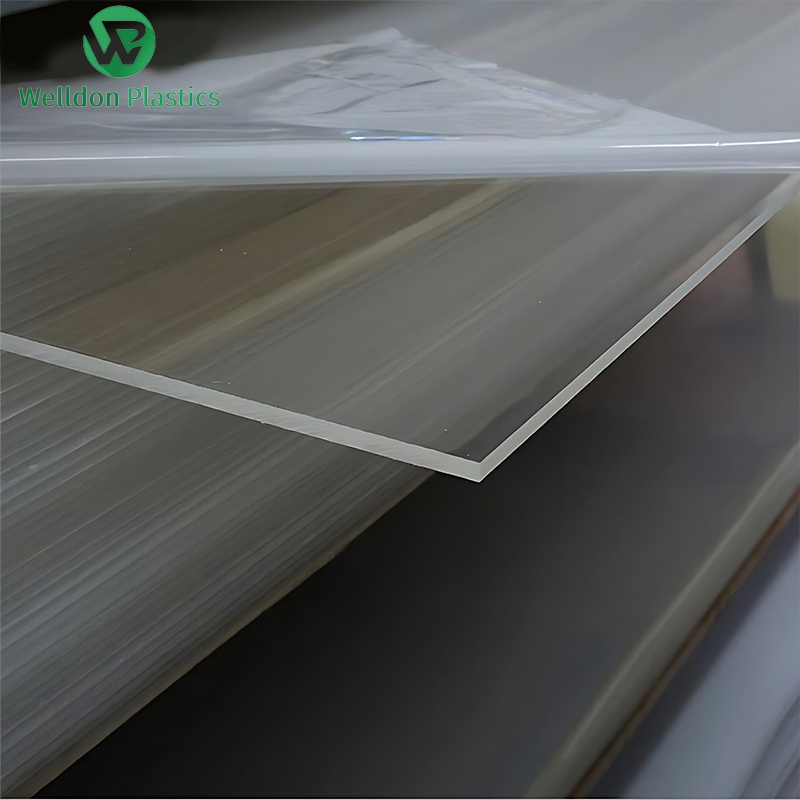

Acrylic Sheet Production: The acrylic sheets are typically produced by either extrusion or casting. This involves polymerizing monomers of methyl methacrylate into polymethyl methacrylate (PMMA), forming the base acrylic sheet.

-

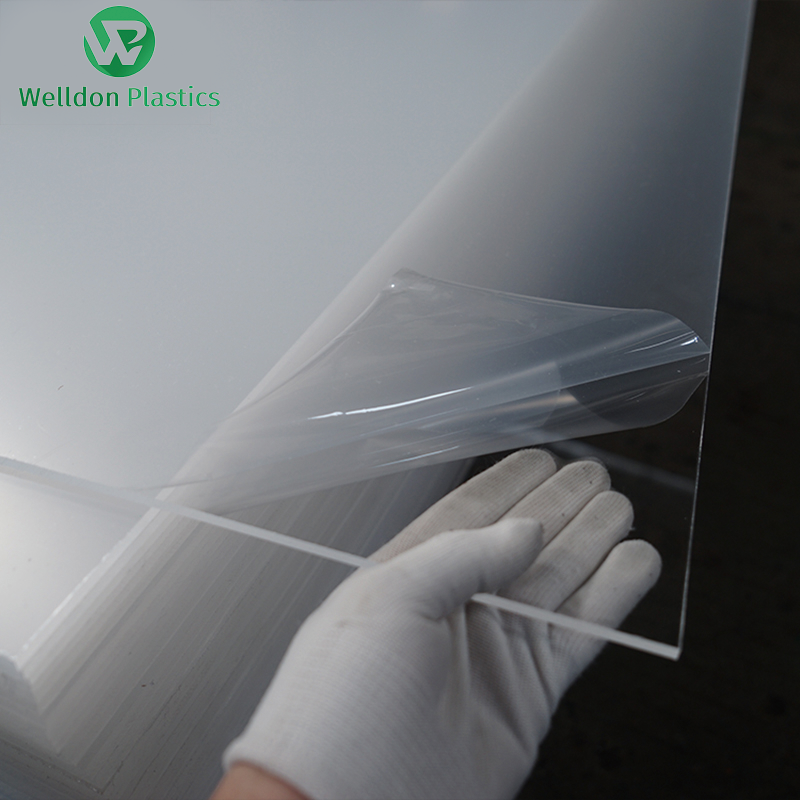

Laminating with PE Film: After the acrylic sheets are formed, a layer of PE film is applied to one or both surfaces. This lamination can be done through a variety of methods, such as using adhesives, heat bonding, or static electricity to ensure the film adheres well to the acrylic surface without permanently bonding to it.

-

Curing and Cutting: Post-lamination, the sheets may undergo additional curing processes, if necessary. Finally, the sheets are cut to desired sizes and shapes, ready for distribution and use.

Benefits Over Other Protective Coatings

-

Non-permanent: Unlike some other coatings which might require solvents or cleaning agents to remove, PE film can be simply peeled away, leaving no residue.

-

Cost-effective: Applying a PE film is generally less expensive than applying other types of protective coatings.

-

Flexible: The film can cover any acrylic sheet regardless of shape or size without affecting the base material's mechanical and optical properties.

PE film acrylic sheets provide an effective solution for maintaining the aesthetic and functional quality of acrylic in various applications, especially where temporary protection is essential. For specific projects, it's always good to consult with suppliers to get the most suitable type of coated acrylic sheet.

-